b

Ti6Al4V, widely described as Grade 5 alloy, characterizes a really notable milestone in materials engineering. Its components – 6% aluminum, 4% vanadium, and the remaining balance being titanium – produces a blend of features that are complex to compete with in distinct building constituent. From the aerospace field to therapeutic implants, and even elite automotive parts, Ti6Al4V’s exceptional durability, rust endurance, and relatively manageable aspect make it one incredibly flexible option. Despite its higher charge, the performance benefits often validate the budget. It's a testament to the way carefully supervised formulating process should truly create an remarkable product.

Examining Stuff Attributes of Ti6Al4V

Titanium 6-4, also known as Grade 5 titanium, presents a fascinating blend of mechanical hallmarks that make it invaluable across aerospace, medical, and engineering applications. Its designation refers to its composition: approximately 6% aluminum, 4% vanadium, and the remaining percentage titanium. This specific alloying results in a remarkably high strength-to-weight equilibrium, significantly exceeding that of pure titanium while maintaining excellent corrosion durability. Furthermore, Ti6Al4V exhibits a relatively high elasticity modulus, contributing to its spring-like behavior and competency for components experiencing repeated stress. However, it’s crucial to acknowledge its lower ductility and higher expense compared to some alternative matrices. Understanding these nuanced properties is necessary for engineers and designers selecting the optimal fix for their particular needs.

Titanium 6-4 alloy : A Comprehensive Guide

6Al-4V titanium, or Ti64, represents a cornerstone material in numerous industries, celebrated for its exceptional symmetry of strength and thin properties. This alloy, a fascinating mixture of titanium with 6% aluminum and 4% vanadium, offers an impressive force-to-weight ratio, surpassing even many high-performance metals. Its remarkable erosion resistance, coupled with superb fatigue endurance, makes it a prized option for aerospace uses, particularly in aircraft structures and engine parts. Beyond aviation, 6Al-4V finds a standing in medical implants—like hip and knee additions—due to its biocompatibility and resistance to flesh fluids. Understanding the alloy's unique characteristics, including its susceptibility to gas embrittlement and appropriate process treatments, is vital for ensuring physical integrity in demanding settings. Its making can involve various procedures such as forging, machining, and additive forming, each impacting the final qualities of the resulting object.

Titanium Alloy 6-4 : Composition and Characteristics

The remarkably versatile composition Ti 6 Al 4 V, a ubiquitous light metal blend, derives its name from its compositional makeup – 6% Aluminum, 4% Vanadium, and the remaining percentage pure metal. This particular formulation results in a component boasting an exceptional integration of properties. Specifically, it presents a high strength-to-weight proportion, excellent corrosion protection, and favorable thermal characteristics. The addition of aluminum and vanadium contributes to a enduring beta state structure, improving bendability compared to pure metal. Furthermore, this substance exhibits good solderability and fabricability, making it amenable to a wide assortment of manufacturing processes.

Ti-6Al-4V Strength and Performance Data

The remarkable combination of yield strength and long-term protection makes Ti6Al4V a commonly used material in aviation engineering, therapeutic implants, and premium applications. Its peak load capacity typically operates between 895 and 950 MPa, with a yield strength generally between 825 and 860 MPa, depending on the particular tempering operation applied. Furthermore, the product's density is approximately 4.429 g/cm³, offering a significantly positive strength/weight proportion compared to many standard carbon steels. The Young's modulus, which signifies its stiffness, is around 113.6 GPa. These markers add to its comprehensive application in environments demanding both high mechanical reliability and lastingness.

Mechanical Properties of Ti6Al4V Titanium

Ti6Al4V compound, a ubiquitous precious metal alloy in aerospace and biomedical applications, exhibits a compelling suite of mechanical capabilities. Its tensile strength, approximately 895 MPa, coupled with a yield resilience of around 825 MPa, signifies its capability to withstand substantial pressures before permanent deformation. The stretch, typically in the range of 10-15%, indicates a degree of malleability allowing for some plastic deformation before fracture. However, breakability can be a concern, especially at lower temperatures. Young's flexural modulus, measuring about 114 GPa, reflects its resistance to elastic twisting under stress, contributing to its stability in dynamic environments. Furthermore, fatigue durability, a critical factor in components subject to cyclic application, is generally good but influenced by surface quality and residual stresses. Ultimately, the specific mechanical response depends strongly on factors such as processing tactics, heat tempering, and the presence of any microstructural irregularities.

Deciding on Ti6Al4V: Functions and Gains

Ti6Al4V, a favored titanium composition, offers a remarkable mix of strength, material resistance, and life-friendliness, leading to its massive usage across various domains. Its somewhat high valuation is frequently endorsed by its performance features. For example, in the aerospace industry, it’s critical for fabricating flying machines components, offering a outstanding strength-to-weight ratio compared to typical materials. Within the medical sector, its fundamental biocompatibility makes it ideal for procedural implants like hip and extremity replacements, ensuring persistence and minimizing the risk of disapproval. Beyond these important areas, its also engaged in road vehicle racing parts, exercise accessories, and even purchaser products expecting high capability. Ultimately speaking, Ti6Al4V's unique characteristics render it a significant fabric for applications where concession is not an option.

Analysis of Ti6Al4V Compared to Other Titanium Metals Alloys

While Ti6Al4V, a renowned alloy boasting excellent durability and a favorable strength-to-weight proportion, remains a dominant choice in many aerospace and health-related applications, it's paramount to acknowledge its limitations vis-à-vis other titanium blends. For instance, beta-titanium alloys, such as Ti-13V-11Fe, offer even heightened ductility and formability, making them compatible for complex production processes. Alpha-beta alloys like Ti-29Nb, demonstrate improved creep resistance at boosted temperatures, critical for propulsion components. Furthermore, some titanium alloys, fabricated with specific alloying elements, excel in corrosion durability in harsh environments—a characteristic where Ti6Al4V, while good, isn’t always the best selection. The preference of the proper titanium alloy thus relies on the specific requirements of the aimed application.

Ti64: Processing and Manufacturing

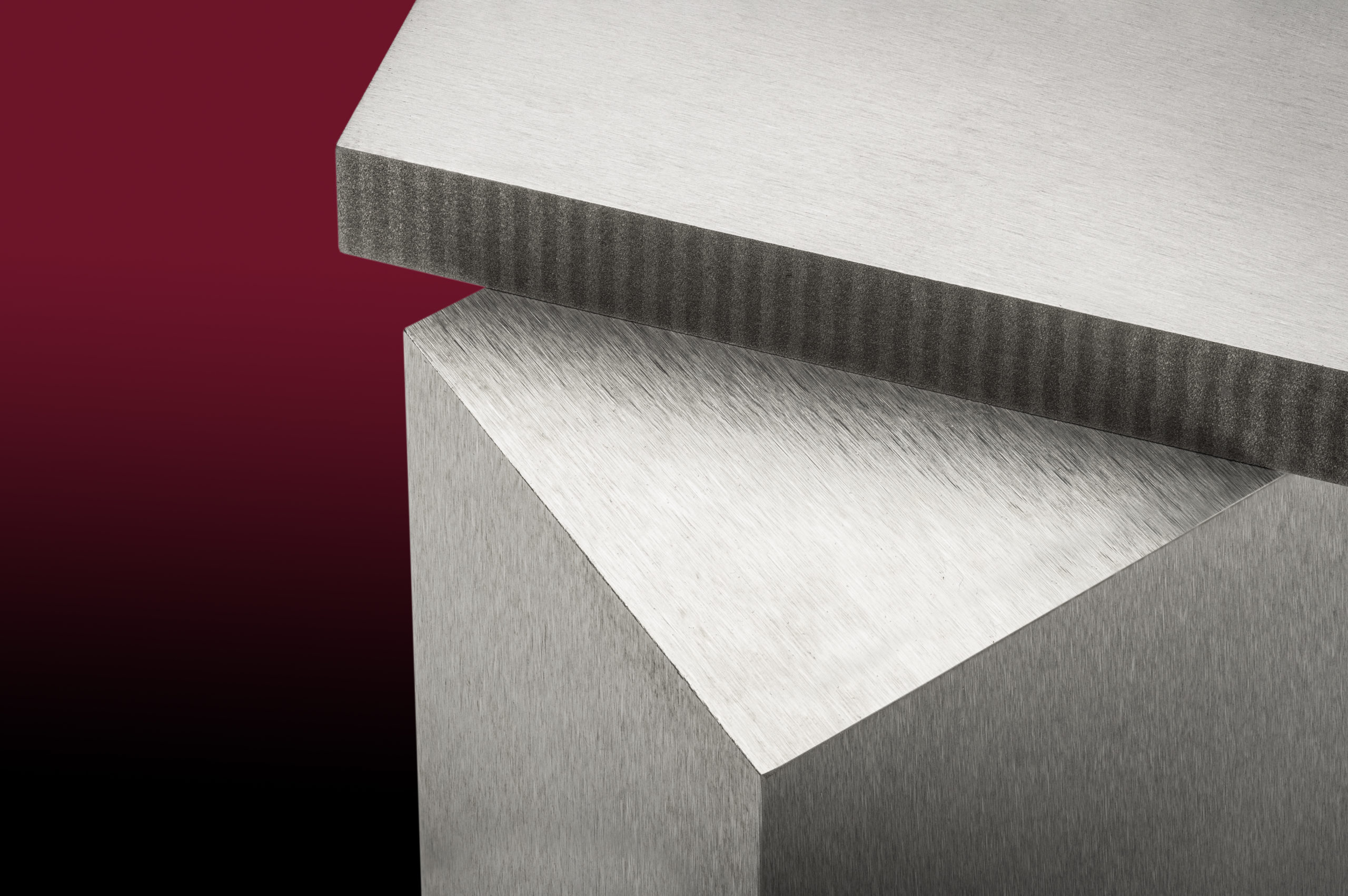

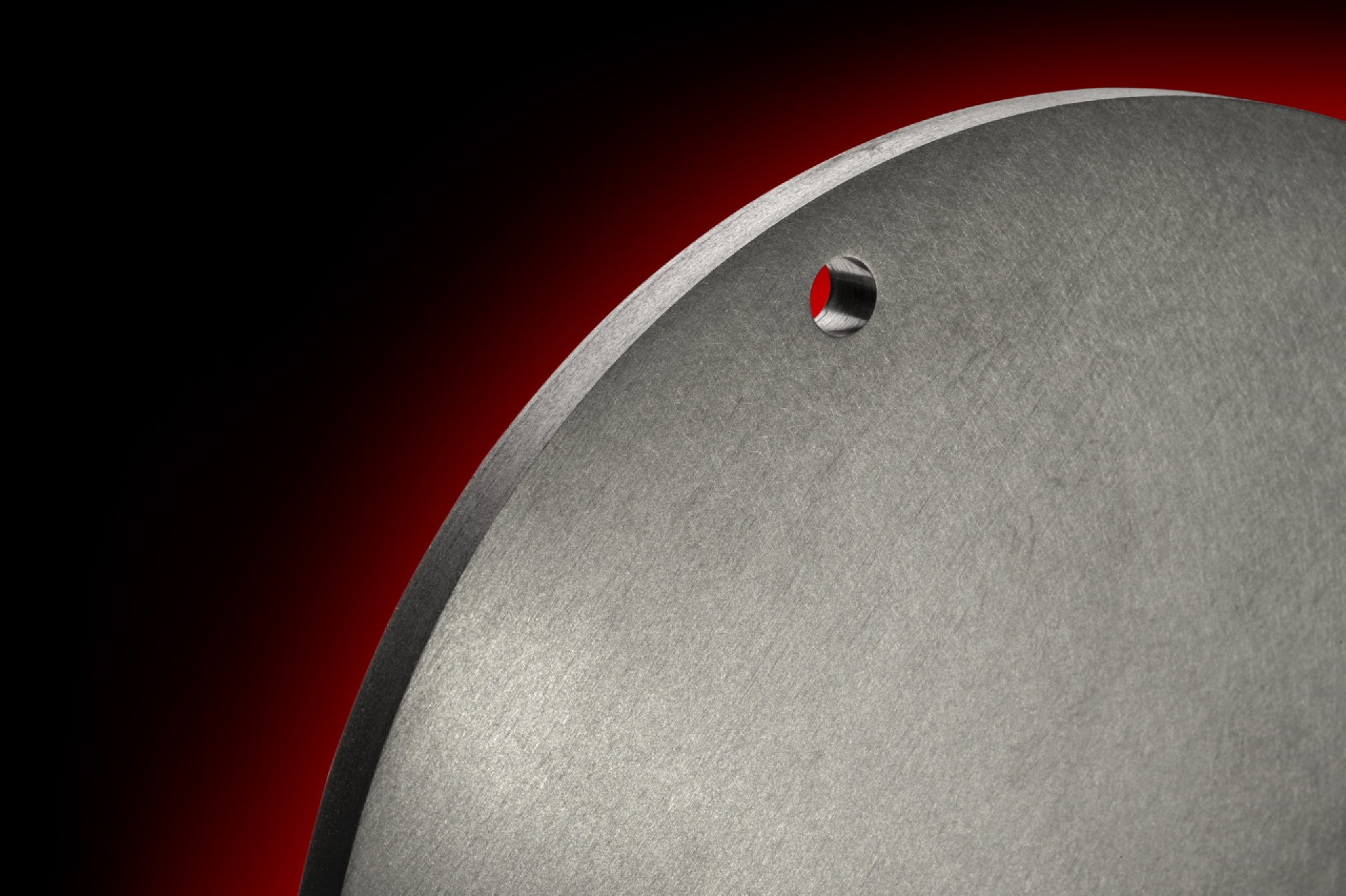

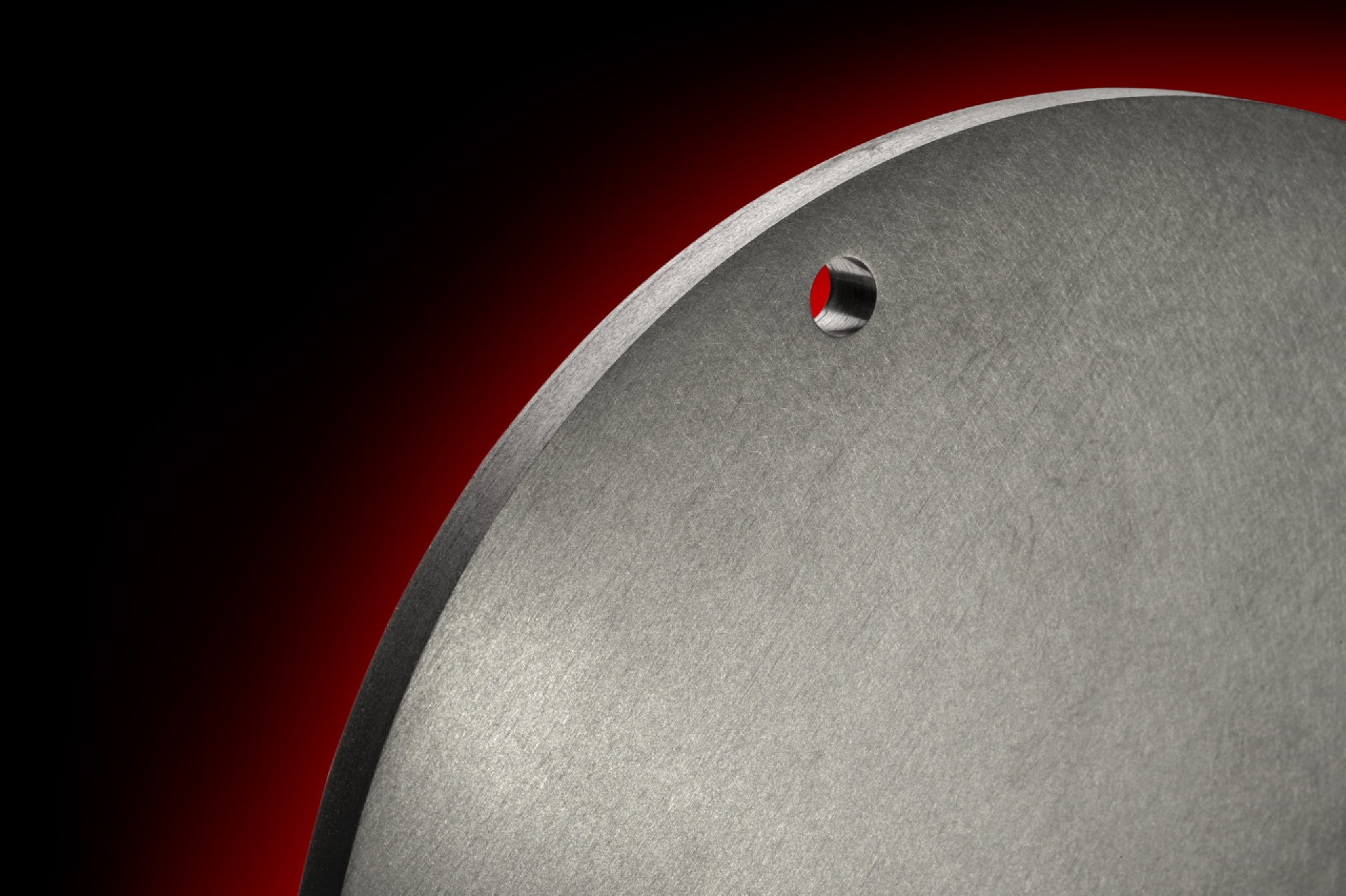

The creation of components from 6Al-4V compound necessitates careful consideration of plethora processing methods. Initial rod preparation often involves laser melting, followed by first forging or rolling to reduce transverse dimensions. Subsequent shaping operations, frequently using plasma discharge finishing (EDM) or CNC control (CNC) processes, are crucial to achieve the desired targeted geometries. Powder Metallurgy (PM|Metal Injection Molding MIM|Additive Manufacturing) is increasingly applied for complex configurations, though compactness control remains a important challenge. Surface layers like anodizing or plasma spraying are often employed to improve rust resistance and surface properties, especially in high-performance environments. Careful thermal control during quenching is vital to manage residual and maintain elasticity within the assembled part.

Oxidation Resilience of Ti6Al4V Titanium

Ti6Al4V, a widely used compound fabric, generally exhibits excellent durability to breakdown in many locales. Its protection in oxidizing contexts, forming a tightly adhering film that hinders extended attack, is a key consideration. However, its behavior is not uniformly positive; susceptibility to spot corrosion can arise in the presence of saline species, especially at elevated levels. Furthermore, current-induced coupling with other elements can induce decay. Specific uses might necessitate careful analysis of the conditions and the incorporation of additional protective strategies like layers to guarantee long-term firmness.

Ti6Al4V: A Deep Dive into Aerospace Material

Ti6Al4V, formally designated titanium 6-4-V, represents a cornerstone component in modern aerospace engineering. Its popularity isn't coincidental; it’s a carefully engineered compound boasting an exceptionally high strength-to-weight balance, crucial for minimizing structural mass in aircraft and spacecraft. The numbers "6" and "4" within the name indicate the approximate shares of aluminum and vanadium, respectively, while the "6" also alludes to the approximate percentage of titanium. Achieving this impressive performance requires a meticulously controlled assembly process, often involving vacuum melting and forging to ensure uniform structure. Beyond its inherent strength, Ti6Al4V displays excellent corrosion longevity, further enhancing its persistence in demanding environments, especially when compared to variants like steel. The relatively high fee often necessitates careful application and design optimization, ensuring its benefits outweigh the financial considerations for particular functions. Further research explores various treatments and surface modifications to improve fatigue features and enhance performance in extremely specialized events.

niobium C103

niobium C103