Inside the scope of industrial workflows, maintaining the stability and functionality of lines is essential. Concentration of filth within pipelines can dramatically restrict flow velocity, lessen production excellence, and raise preservation fees. To solve these problems, line purification techniques have surfaced as notably successful cures for efficient tube purging. A cleaning tool, habitually a rod-like apparatus, is pushed through the conduit, adequately wiping fouling and securing optimal performance

Channel scrubbing techniques offer plentiful assets. They are versatile, capable of washing lines of varied measures and substances. Furthermore, they are productive, fulfilling the task in a aptly short timespan. By minimizing downtime and advancing pipeline performance, pipeline cleaning systems foster expenditure savings and increased operational efficiency

Health-Driven Pipe Systems:

Maintaining pipeline freshness is vital for supporting manufacturing security and superiority of carried materials. Sanitary pigging systems supply a stable way to realize this mission. Pigs, tailored contraptions, are introduced into pipelines to sterilize by eliminating residues and waste

- Assorted kinds of sanitary pigs are accessible, each designed for special cleaning work.

- These pigs are fabricated from constituents that comply with stringent sterile standards.

- Methodical sanitary pigging procedures support eliminating product cross-contamination, increase pipeline survival, and escalate total functionality.

Progressive Pigging Methods for Superior Capability

Across the area of duct management, leading pigging techniques have turned into a vital resource for maintaining maximum productivity and safety. These groundbreaking systems exploit breakthrough schematics and functions to successfully scrub, analyze, and secure lines from impairment. From intelligent pigs fitted with instantaneous surveillance systems to designed pigging apparatus purposed for fine tasks, expansion in this branch is perpetually pushing boundaries. By adopting these technologies, users can greatly enhance pipeline integrity, minimize downtime, and optimize operational productivity.

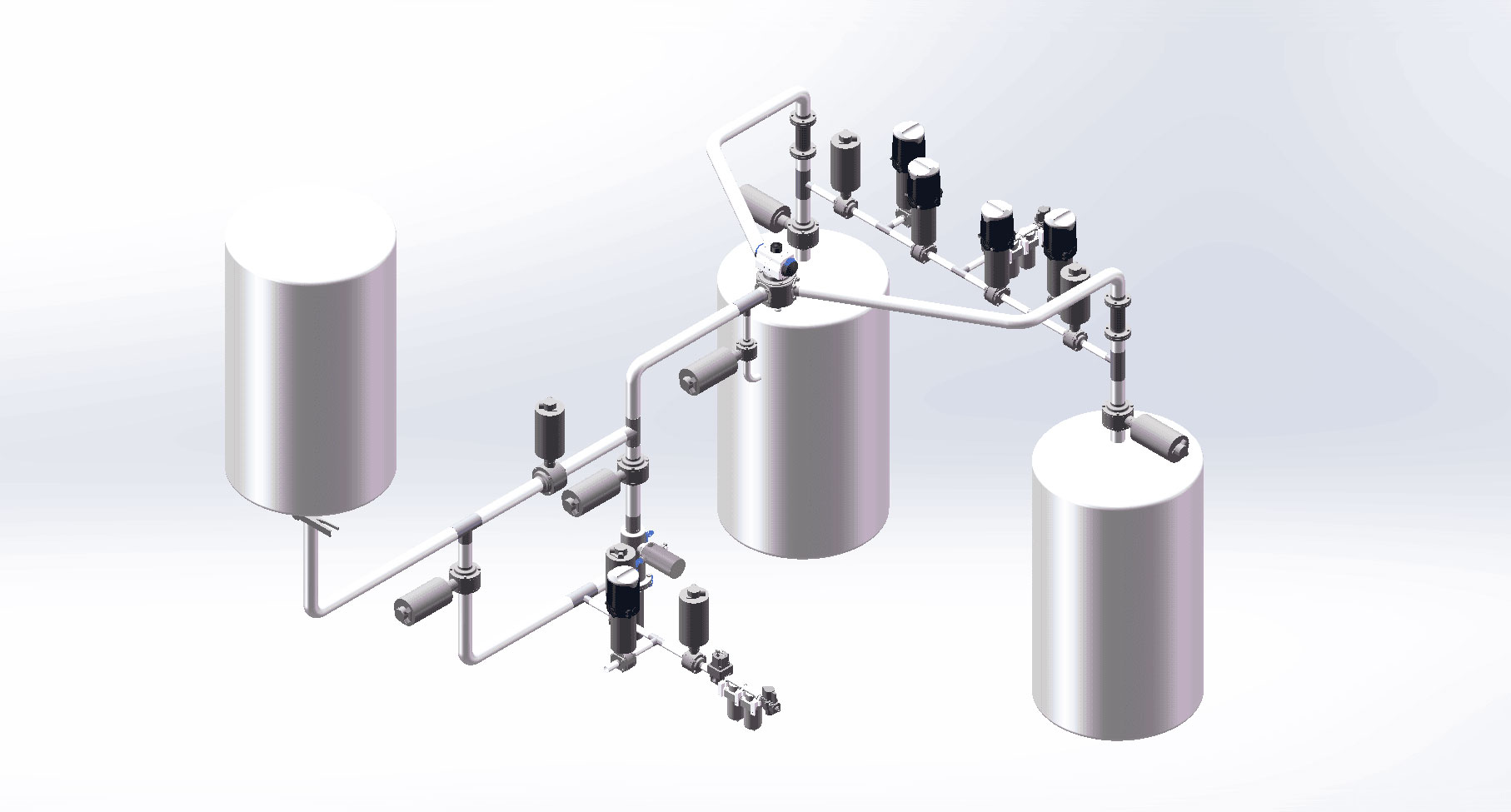

Comprehensive Pigging System Design and Assembly

A full-scale pigging system consists of a fundamental system for pipeline preservation. This system demands the deployment of specialized implements called pigs, which venture through conduits to flush, check, and protect their soundness. The configuration underscores components such as tubing thickness, fabric, pig variation, and operational prerequisites. A thoughtful system guarantees effective pigging jobs while limiting downtime and potential injuries. Installation customs impose careful preparation, skilled experts, and strict adherence to safety directives to secure a secure and fruitful product

Industrial Pigging Systems for Diverse Applications

Factory pigging devices are indispensable devices employed across a sizable collection of industries. These devices advance protected and advanced scrubbing, inspection, and management of pipelines and other tube-like frameworks. Pigging comprises installing specialized contraptions known as pigs through pipes to conduct numerous operations. Regular types of industrial pigging tools comprise cleaning pigs, inspection pigs, and carrier pigs. Cleaning pigs are fabricated to extract debris, build-up, and impurities from pipelines. Inspection pigs are installed with devices that harvest information about the status of pipe faces. Transport pigs are used to shift fluids through pipelines. The use of industrial pigging products yields numerous gains, such as minimized downtime, boosted pipeline steadfastness, and heightened operational performance. These products are widely operated in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.Thorough Study of Pipeline Pigging

Pipeline pigging is an vital operation used within the oil and gas arena to inspect pipelines. This key methodology consists of inserting dedicated gadgets, named pigs, into the pipeline. Pigs are built to navigate the track of the pipeline, carrying out various functions.

Various categories of pigs are on call, each built for a specific goal. Common functions of pipeline pigging encompass auditing for defects, washing, and protective layer application.

- Positive Outcomes of Pipeline Pigging

- Consequences on Operational Efficiency

- Kinds of Pipeline Pigs

Efficient Sanitation utilizing Pigging Setups

Pigging methods provide a trustworthy answer for maintaining sanitation inside tubes. These technologies make use of dedicated instruments that pass through the channel layout, productively scrubbing fouling. The operation is especially valuable for areas that call for rigorous sterility norms. Pigging processes provide a budget-friendly and timely approach for sanitizing pipelines, decreasing the exposure of taint.

Deciding on Pigging Instruments for Targeted Requirements

Pigging apparatus plays a significant role in productive pipeline work. When opting for pigging devices, it is critical to consider the concrete prerequisites of your operation. This entails evaluating details such as pipeline thickness, flow volume, product type, and restoration goals.

Different pigging options are obtained, each fabricated for distinct causes. For example, some pigs are built for surveillance, while others are deployed for clearing pollutants or segmenting product groups.

As well, pigging machinery materials should be agreeable with the shipped substance.

It is typically advisable to consult a technician in pigging solutions to secure that you elect the most appropriate hardware for your particular specifications.

Conduit Maintenance Methods - A Practical Approach

Flow line pigging present a extensive variety of benefits for areas relying on tubes. By effectively disinfecting and inspecting line insides, pigging systems contribute to operational productivity and reduce maintenance charges.

A fundamental asset of pigging systems is their potential to remove fouling such as dirt, debris, and rusts. This frequent purging helps maintain unhindered pipeline discharge and deters costly downtime.

What's more, pigging systems can be operated to monitor the health of pipelines, discovering likely anomalies before they expand into major threats. This precautionary method assists to boost endurance of pipelines and cut back overall maintenance outlays.

Promoting Hygiene in Pigging Functions

Piggy rearing operations substantially lean on appropriate hygiene guidelines to restrain the spread of infections. Following rigorous hygiene procedures facilitates a vital environment for pigs, that contributes to superior health outcomes and yield.

Frequent cleaning and disinfection of sites is fundamental to block the presence of harmful pathogens. Effective excrement management additionally functions a important part in sustaining hygiene.

In pigging products addition, {workers