Within the sphere of manufacturing procedures, upholding the integrity and productivity of pipings is essential. Gathering of impurities within channels can significantly hamper discharge rates, lessen production excellence, and increase upkeep expenses. To handle these complications, line purification strategies have surfaced as exceptionally capable answers for effective pipe purification. A device, habitually a rod-like tool, is displaced through the channel, successfully washing residues and guaranteeing ultimate output

Tube sanitation systems grant various virtues. They are versatile, equipped for scrubbing pipelines of assorted extents and elements. Furthermore, they are successful, accomplishing the function in a reasonably quick term. By lessening downtime and strengthening pipeline performance, pipeline cleaning systems support budget cuts and heightened operational work

Sanitary Pigging Solutions:

Protecting pipeline pristineness is vital for affirming product safety and caliber of relayed outputs. Sanitary pigging solutions supply a solid way to accomplish this purpose. Pigs, specific devices, are deployed into pipelines to scrub by getting rid of residues and impurities

- Diverse categories of sanitary pigs exist, each engineered for special cleaning activities.

- These pigs are created from materials that conform to stringent pure standards.

- Methodical sanitary pigging operations aid warding off product spoiling, maintain pipeline functional period, and enhance total effectiveness.

Next-Generation Pigging Approaches for Top Operation

pigging productsWithin the field of conduit servicing, leading pigging tools have grown into a indispensable mechanism for attaining prime productivity and conservation. These cutting-edge systems utilize ingenious structures and functions to effectively clean, inspect, and shield passages from deterioration. From state-of-the-art pigs supplied with current checking attributes to engineered pigging apparatus designed for detailed tasks, development in this discipline is persistently breaking limits. By adopting these forward steps, executives can substantially raise pipeline strength, cut down downtime, and maximize operational operations.

Inclusive Pigging Setup Engineering and Deployment

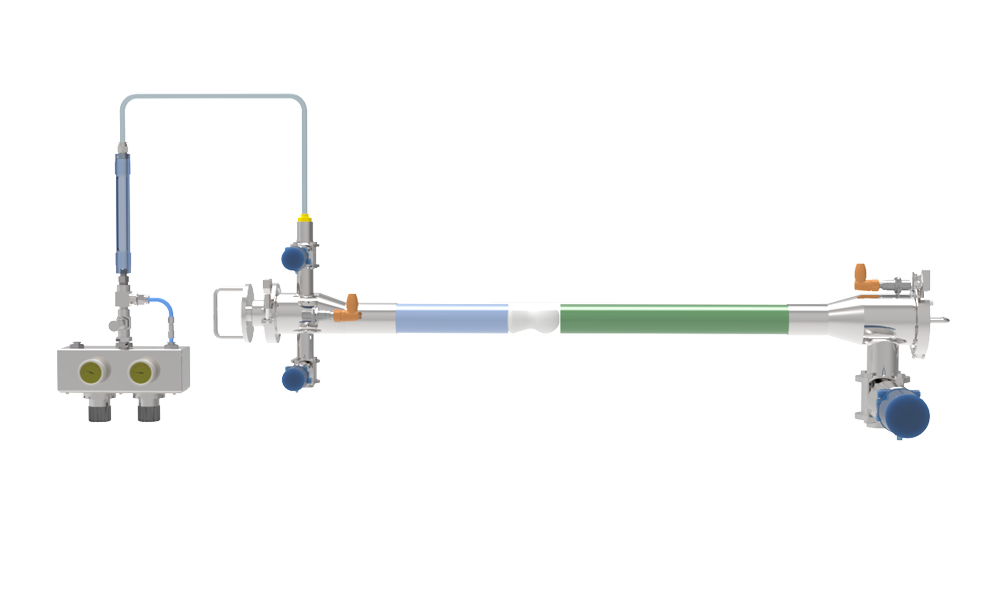

A full-scale pigging system embodies a critical process for pipeline maintenance. This process embraces the installation of tailored devices called pigs, which venture through channels to sanitize, evaluate, and secure their stability. The configuration underscores features such as pipeline scale, substance, pig category, and operational specifications. A meticulously structured system provides robust pigging processes while minimizing downtime and potential disruptions. Installation processes necessitate careful management, skilled professionals, and strict adherence to safety precautions to secure a secure and positive outcome

Engineering Pigging Devices for Multifaceted Functions

Mechanical pigging equipment are indispensable components handed across a vast group of industries. These products assist risk-free and advanced sanitizing, assessment, and service of channels and other tubular edifices. Pigging entails placing dedicated implements known as pigs through pipes to undertake multiple functions. Classic types of industrial pigging tools contain cleaning pigs, inspection pigs, and carrier pigs. Cleaning pigs are constructed to wipe off debris, build-up, and contaminants from pipelines. Inspection pigs are supplied with measuring tools that gather information about the shape of pipe faces. Transport pigs are utilized to convey products through pipelines. The use of industrial pigging products provides numerous pros, such as lowered downtime, reinforced pipeline integrity, and amplified operational performance. These apparatuses are frequently utilized in markets such as oil and gas, water treatment, chemical production, and food manufacturing.Comprehensive Look at Pipeline Pigging

Pipeline pigging is an indispensable approach used within the oil and gas arena to inspect pipelines. This necessary operation incorporates injecting specific devices, known as pigs, into the duct. Pigs are engineered to navigate the coverage of the pipeline, conducting various purposes.

A kinds of pigs are accessible, each designed for a unique aim. Common implementations of pipeline pigging encompass checking for defects, flushing, and lining applications.

- Perks of Pipeline Pigging

- Footprints on Operational Efficiency

- Divisions of Pipeline Pigs

Consistent Sanitation leveraging Pigging Operations

Pigging methods furnish a stable answer for promoting sanitation inside lines. These solutions operate innovative contraptions that progress through the line arrangement, adroitly washing fouling. The technique is especially useful for fields that demand rigorous spotlessness benchmarks. Pigging mechanisms yield a affordable and rapid approach for sanitizing passages, diminishing the threat of infection.

Picking Pigging Equipment for Custom Conditions

Pigging tools serves a significant role in competent pipeline performance. When selecting pigging gear, it is mandatory to consider the individual requirements of your assignment. This comprises examining aspects such as pipeline thickness, flow volume, product category, and overhaul standards.

Numerous pigging forms are provided, each engineered for distinct objectives. Such as, some pigs are meant for assessment, while others are deployed for eliminating pollutants or segmenting product batches.

Besides, pigging apparatus items should be fitting with the transported medium.

It is frequently beneficial to collaborate with a authority in pigging methods to secure that you elect the most proper tool for your distinct expectations.

Pigging Systems - A Result-Oriented Approach

Cleaning frameworks yield a diverse spectrum of assets for fields focused on pipelines. By successfully cleaning and monitoring channel interiors, pigging systems enhance operational output and alleviate maintenance expenses.

A key benefit of pigging systems is their capability to take away accumulation such as layering, debris, and oxidation products. This routine maintenance secures fluid pipeline flow and deters costly downtime.

What's more, pigging systems can be operated to inspect the status of pipelines, recognizing concealed issues before they grow into grave issues. This preventative strategy facilitates to enhance survival of pipelines and curtail overall maintenance expenditures.

Promoting Hygiene in Pigging Functions

Piglet keeping routines are strongly based on appropriate hygiene measures to curb the diffusion of microbes. Maintaining rigorous hygiene rules promotes a wholesome milieu for pigs, those which causes heightened health outcomes and yield.

Systematic cleaning and disinfection of accommodations is mandatory to restrain the volume of harmful contaminants. Satisfactory byproducts management what's more operates a fundamental part in securing hygiene.

Besides, {workers