Across the intensive zone of electric networks, busbar fabrication involves distinctive difficulties. Going from exact assembly to effective positioning, every step requires attentive detail and creative strategies. Contemporary production methods have transformed busbar handling, delivering exceptional efficiency and output. State-of-the-art equipment including computer-driven trimming, folding, and fusing units provide exactitude, uniformity, and decreased processing periods.

These breakthroughs effect actual payoffs for clients. Busbar sets are engineered briskly and harmoniously, trimming non-operations and facilitating deadline adherence. Besides that, the fundamental fineness of advanced practices leads to busbars exhibiting better conduction and longevity, securing trustworthy power distribution over duration.

- Autonomous snipping: Exact chipping processes ensure precise and replicable figures, decreasing junk and improving aggregate efficacy

- Forming mastery: State-of-the-art contouring devices make precise inflections and corners, enabling complicated busbar constructs and bespoke setups

- Welding Prowess: Automated welding processes provide strong and reliable connections, ensuring the integrity of busbar assemblies

By embracing these cutting-edge solutions, businesses can optimize their busbar processing operations, achieving unparalleled efficiency and performance. Tomorrow’s electric frameworks are shaped by invention, with contemporary busbar fabrication techniques leading this advancement.

Exact Electrical strip Folding toward Voltage Distinction

Reaching peak energy transmission calls for refined and painstaking electric strip flexing practices. Power strips, as essential carriers conveying electric current, need to be molded with remarkable exactness to guarantee effective energy transfer and reduce opposition. Such exactness is crucial in mitigating temperature rise and prospective failures in electric setups. Through the utilization of advanced bending machinery and skilled craftsmanship, manufacturers can create busbars that meet the stringent requirements of diverse electrical applications.

- Prime charge transfer

- Curtailed energy loss

- Boosted system reliability

Upgrade Personal Charge carrier Production incorporating a versatile control machine

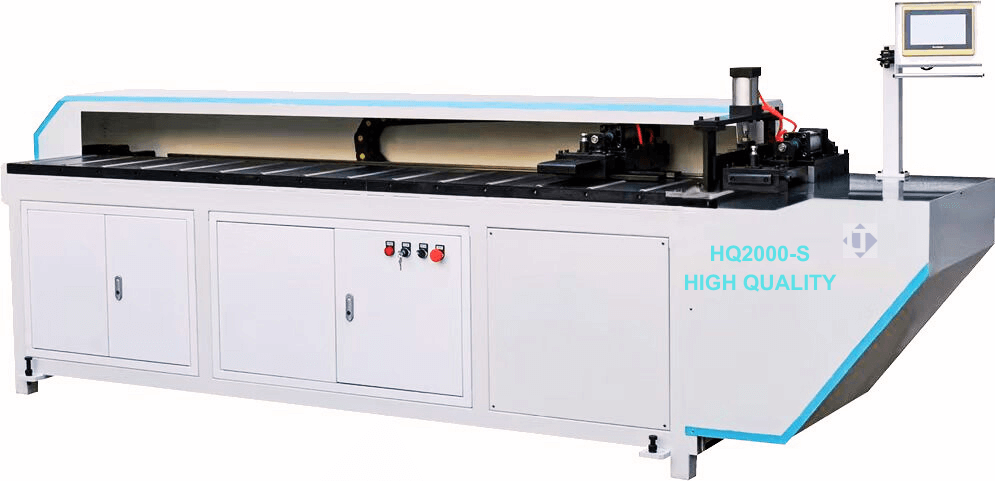

Are you searching for an efficient approach to execute your power strip creation tasks? Select the novel hybrid fabrication system! This advanced instrument merges three vital operations within one platform, delivering a total approach for shearing, flexing, and stamping power strips with supreme correctness.

- Asset 1

- Benefit 2

- Feature 3

Built with durable materials and simple interface, the triple-operation current apparatus is crafted to yield superior production with lowered idle times. Elevate your current bar processing sooner employing this crucial apparatus!

Computerized Copper strip Assembly: Increasing Productivity and Exactness

The fabrication field continually pushes for maximizing productivity and correctness. Electrical bar development, a primary action in energy transmission engineering, complies too. Robotized conductor manufacturing solutions are transforming the sector through substantially increasing throughput while maintaining excellent precision. These progressive operations apply modern equipment such as computerized control and laser slicing technology to construct electrical bars with superb consistency and pace.

Via computerizing monotonous chores, these platforms empower staff to concentrate on complex duties. Such advancement improves total output and decreases mistakes, resulting in superior conductor items. Furthermore, digitized copper strip production apparatuses present superior traceability and analytic functions, furnishing useful reports on processing mechanisms and aiding continuous enhancement.

Leading-Edge Copper bar Handling Solutions

The necessity for prime electronic infrastructures rises prompting breakthroughs in electric contact fabrication. Next-generation technologies are emerging revolutionizing this field, enabling the manufacture of highly precise and efficient busbars. Such improvements include next-level trimming technologies including laser stripping and electron discharge machining (EDM), providing superior exactitude, surface enhancement, and raw material removal. In addition, the incorporation of digital drafting alongside manufacturing software grants exact handling of geometry and limits scrap

- Streamlined procedures in busbar machining streamline production, increasing efficiency and reducing lead times|Automated apparatuses in conductor manufacturing optimize workflows, boosting productivity and cutting delays|Mechanized tools in power strip fabrication enhance output, augmenting speed and minimizing downtime|Computerized devices in current bar assembly improve cycles, elevating effectiveness and shortening turnarounds|Digitized systems in copper bar processing advance throughput, maximizing rapidity and trimming wait periods|Robotic equipment in electric contact crafting upgrade sequences, heightening competence and limiting stoppage|Intelligent machines in charge carrier production refine operation, increasing capacity and lowering processing times|Streamlined units in electrical bar treatment boost productivity, accelerating results and decreasing idle intervals

- Evaluation frameworks play a crucial role in ensuring the quality and consistency of machined busbars, detecting any deviations from specifications|Observation gadgets hold vital importance in maintaining integrity and uniformity of fabricated conductors, identifying anomalies relative to standards|Measurement technologies serve critical functions in preserving excellence and regularity of manufactured power strips, pinpointing divergences against criteria|Detection instruments perform key roles in upholding precision and stability of constructed current bars, recognizing variants from requirements|Tracking mechanisms are essential in securing accuracy and uniformity of processed copper strips, signaling disparities from benchmarks|Evaluation tools have importance in guarding fidelity and steadiness of crafted electric contacts, flagging inconsistencies to parameters|Monitoring devices are instrumental in affirming reliability and evenness of assembled charge carriers, spotting departures from norms|Data analytics systems are fundamental in assuring quality and homogeneity of machined electrical bars, marking deviations against specifications

Refining Electric strip Development with Advanced Equipment

Within transforming voltage architectures, modernizing charge carrier processing is necessary. Contemporary progress in fabrication tools has transformed these operations, allowing fabricators to deliver superior conductors with higher productivity and accuracy. High-speed automated cutting systems ensure accurate and consistent dimensions, in addition exquisite binding equipment furnish robust and sure fastenings. This progress realizes trimming manufacturing spans plus decreasing raw substance losses, enhancing ecological responsibility.

Advances through Automation in Busbar Manufacturing

Power strip production experiences a dramatic shift facilitated by integrating automated systems. Computerized automation upgrades operations involving carving, folding, sealing, and checking. The transformation offers multiple perks such as elevated capacity, better item consistency, decreased workforce spending, and reduced mistakes.

- Hence, current bar vendors deliver refined outputs quicker, addressing tough specifications of assorted industries

- {Furthermore, automation enhances workplace safety by reducing manual labor involving workers to potentially hazardous conditions|Moreover, robotics improves occupational health lowering physical tasks exposing staff to risky environments|Additionally, intelligent systems boost labor protection by minimizing manual efforts subjecting employees to unsafe situations|Besides that, computerized operations augment workforce security by cutting down physical jobs placing workers in dangerous settings|Further, mechanized functions uplift occupational safety by decreasing manual duties involving personnel in harmful conditions|Also, digitized procedures raise workplace protection by lessening human effort exposing laborers to hazardous areas|Likewise, automated workflows increase employee security by limiting manual tasks facing crew to risky circumstances|Similarly, streamlined processes improve staff safety by reducing physical labor subjecting workers to perilous zones

Going forward, copper strip processing employing intelligent systems is supposed to grow steadily

Robust Electrical contact Processing Devices

Within electric engineering, advanced conductor machining tools are essential for producing dependable and effective energy delivery frameworks. These complex systems apply intelligent innovations to manipulate current bars with superior accuracy and rapidity. Covering piercing and shearing along with folding and crafting, these adaptable systems perform multiple jobs accurately, assuring maximum efficacy and endurance of finished items. Applying strong resources and intelligent management frameworks permits these systems to run productively and consistently in tough circumstances

- Intelligent control systems ensure precise alignment of busbars throughout the processing cycle|Smart regulation frameworks guarantee accurate positioning of conductors during entire fabrication operations|Programmable management solutions provide exact arrangement of power strips throughout production sequences|Computer-aided supervision platforms deliver precise orientation of current bars across processing steps|Mechanized monitoring tools secure accurate setup of copper strips during manufacturing phases|Digitized adjustment apparatuses facilitate exact alignment of electric contacts through assembly stages|Robotic command mechanisms maintain precise positioning of charge carriers during fabrication runs|Streamlined control devices assure accurate layout of electrical bars throughout machining procedures

- Robust construction withstands the rigors of continuous operation in industrial settings|Solid manufacturing sustains harsh demands of nonstop use in factory environments|Hardy fabrication endures stresses of prolonged function within production areas|Reinforced design tolerates strains of sustained activity under workshop conditions|Stout assembly resists impact of relentless service inside industrial facilities|Tenacious build copes with pressures of endless operation in manufacturing plants|Resistant structure faces challenges of unceasing work across factory contexts|Hardwearing framework stands up to trials of nonstop performance in production sites

- Efficient processing reduces production time and increases overall productivity|Effective machining shortens manufacturing periods and boosts total output|Quick fabrication lowers operation duration and heightens aggregate yield|Speedy manufacture cuts assembly intervals and enhances combined efficiency|Accelerated production diminishes process time and advances broad throughput|Expedited creation truncates working spans and improves overall performance|Prompt processing contracts operational lengths and raises total capacity|Fast development shrinks fabrication cycles and escalates general productivity

Utilizing cutting-edge copper bar treatment machinery has reshaped fabrication procedures, permitting manufacture of improved, steady circuitry systems catering to increasing demands of present-day electrical uses.

Futuristic Conductor Curving dedicated to Complicated Layouts

Throughout the progressing field of electric circuitry engineering, meticulousness in item production is vital. Electrical contacts, necessary conductors enabling current flow, often involve complex bending formats to support multiple uses. Typical twisting procedures generally struggle with intricate formats, resulting in unsatisfactory effects. Employing futuristic electrical bar contouring techniques transforming practices by enabling creation of complex layouts with extraordinary maneuverability.

- Leveraging cutting-edge CNC equipment, these sophisticated units provide perfect uniformity with each fold

- The software controlling these platforms supplies clear controls, empowering specialists to fabricate detailed bending profiles efficiently

- Moreover, the machinery smoothly adapts to different substances, broadening its applicability within diverse industrial fields

The innovation in electric strip forming supports specialists to fulfill sophisticated schemes, delivering refined voltage capacity and diminished manufacturing outlays.

Attaining Capability by 3D Busbar Fabrication

{Revolutionizing power distribution systems, 3D busbar fabrication offers an innovative approach to optimize efficiency and performance|Transforming energy transmission networks, three-dimensional conductor crafting provides a novel method to enhance productivity and output|Changing electric supply busbar punching bending cutting machine architectures, 3D power strip making introduces a fresh path to boost effectiveness and results|Updating circuitry distribution frameworks, three-dimensional current